Welcome to the OSP Advantage

Since 1945, we have what it takes to quickly incorporate your design into a finished product. Our Product Review staff was built from the ground up and is exceptionally skilled and focused on serving your unique requirements. Consisting of Manufacturing Engineering, Quality Engineering, In-House Tool Design, and a Process Review Team, our ability to transform your design into a completed part is unparalleled! Our mission is to ensure a smooth transition from your concept to full production — WELCOME to the OSP Advantage!

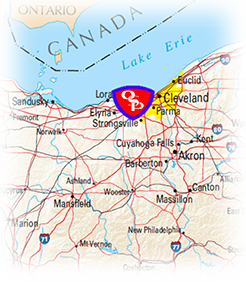

Ohio Screw Products, Inc.

818 Lowell St

Elyria, OH 44035

P: 440-322-6341

Copyright © Ohio Screw Products, Inc. All rights reserved. Site Designed and hosted by Design-2-Part Web Design.